Special Gas Conveying Cabinet for Flammable and Explosive Corrosive and Toxic Gases

Product Description:

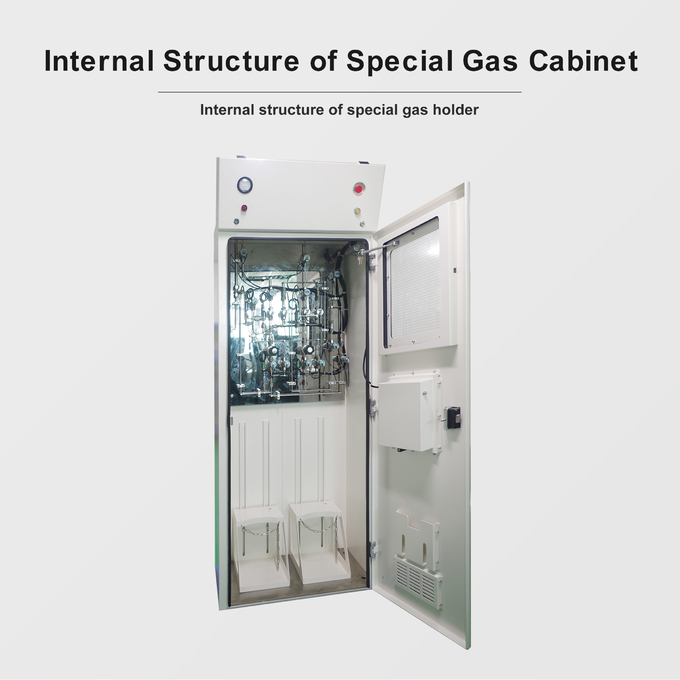

Special gas conveying cabinet is designed for the supply of flammable and explosive, corrosive, toxic and other dangerous gas supply and supply system, according to the category can be divided into: fully automatic, semi-automatic and manual operation. The basic functions include automatic blowing, automatic switching and automatic safety cut-off in case of emergency (when the set alarm signal is triggered) The fully automatic gas cabinet realizes the safe and effective operation of the equipment by adopting the PLC control and touch screen as the man-machine interface, and by means of the equipment-installed pressure sensors, pneumatic valves, over-flow meters, etc. The internal PLC programmed with the safe and effective operation of the equipment is designed for the supply of hazardous gases such as flammable, explosive, corrosive and toxic. Its internal PLC programmed safety interlock function and the reasonable selection and layout of high purity valves not only satisfy the requirements of continuous supply of special gases and high purity in the production process of semiconductor process, but also ensure the normal production of the factory and personal safety of the employees.

Features:

① Simple operation:

② control software compatibility: through different settings, can be applied to different gases to achieve better results.

③ System stability: PLC as the main control body, action is true, low failure rate, high stability.

④ Good safety: The safety measures of this gas cylinder cabinet are differentiated between hardware and software.

Alarm record function: All alarm messages are recorded in detail, including alarm time, end time, acknowledgement time, message summary, etc. Users can clearly check all operations or alarm records.

(6) Signal output: network or wiring output, two ways for signal output.

(vii) Support in other aspects: The gas cabinet control system can be operated and controlled remotely by means of a network.

Technical Parameters:

| Electricity requirements | AC 220V/50Hz 0.6KW |

| Auxiliary gas | pneumatic valve control pressure: 80 Psi ± 10 Psi (compressed air or pneumatic nitrogen); GN2 (vacuum operation): 90 Psi ± 10 Psi, PN2 (purge operation): 80 Psi ± 10 Psi |

| Operating ambient temperature | between 0°C and 35°C |

| Ambient humidity | non-condensing condition 0 ~ 80 |

| Equipment spray | water pressure: 3 ~ 4Bar |

| Water flow rate | 145LPM @ 2.1barg |

FAQ:

Q: What is a special gas cabinet?

Specialty gas cabinet is a kind of equipment for storing and delivering specialty gases, which is usually used in semiconductor, photovoltaic, electronic and other industries. It can safely manage and accurately control special gases to ensure the quality and supply stability of the gases.

Q: What types of special gas cabinets are available?

There are mainly manual, semi-automatic and fully automatic special gas cabinets.

Q: What should I pay attention to the installation of special gas cabinet?

The installation location should be chosen in a well-ventilated, dry place without fire source.

Ensure the stability of the equipment during installation, avoid tilting or shaking.

The connecting pipes should be made of materials that meet the requirements, and make sure that they are firmly connected and without leakage.

Q: How to use the special gas cabinet correctly?

Before using, you should read the operation manual of the equipment carefully to understand the performance and operation method of the equipment.

Conduct gas transportation and control according to the specified operation procedures to avoid misoperation.

Regularly check and maintain the equipment to ensure the normal operation of the equipment.

Q: How to ensure the safe operation of the special gas cabinet?

Install gas leakage detection devices to detect leakage and take measures in time.

Train operators to improve safety awareness and operation skills.

Regular safety inspection and maintenance of the equipment to ensure the safety performance of the equipment.

Q: What maintenance work is required for the special gas cabinet?

Regularly check the sealing of the equipment to ensure no leakage.

Clean the surface of the equipment to keep it clean and sanitary.

Check the wear and tear of valves, pipes and other parts, and replace damaged parts in time.

Q: What is the maintenance cycle of the special gas cabinet?

Maintenance cycle according to the frequency of use of the equipment and environmental conditions, generally recommended every six months to one year for a comprehensive maintenance.

Q: What should be done when the gas cabinet malfunctions?

First stop using the equipment and cut off the gas supply.

Check the fault phenomenon and determine the cause of the fault.

Take appropriate troubleshooting measures according to the cause of failure, such as replacing damaged parts, repairing electrical faults, etc.