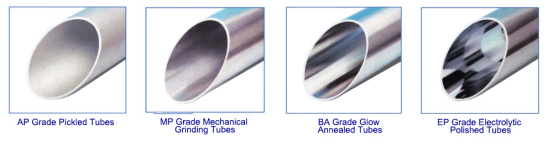

Stainless steel pipes are classified into BA grade (Bright Annealed) and EP grade (Electro Polished) mainly to meet the requirements of different application scenarios for pipe surface cleanliness, corrosion resistance and roughness. These two grades have different treatment processes and are suitable for different industrial environments, especially in high purity gas or liquid transport systems. It can be distinguished from the following four aspects.

1. Different surface treatment processes

BA grade (bright annealing): high-temperature heat treatment under the protection of reducing atmosphere (such as hydrogen or argon), eliminating the internal stress of the steel pipe, and at the same time, forming a passivation film, so that the surface is smooth and clean, and the roughness Ra ≤ 0.4 μm.

EP grade (electrolytic polishing): on the basis of BA tube, further electrochemical polishing treatment is carried out to make the surface smoother, with roughness Ra ≤ 0.15 μm, and to enhance corrosion resistance.

2. Cleanliness and corrosion resistance

BA grade is suitable for high purity gas transport (e.g. semiconductor, pharmaceutical industry), but EP grade is suitable for ultra-high purity environment (e.g. microelectronics, optoelectronics industry) due to electrolytic polishing, which makes the surface smoother and reduces the particle adhesion.

EP grade has better corrosion resistance than BA grade due to the formation of a denser chromium oxide film after electrochemical polishing.

3. Cost and applicable industries

BA grade has lower cost and is suitable for most high purity gas systems (e.g. compressed air, chemical delivery).

EP grade is more costly and is mainly used in areas with extremely high cleanliness requirements (e.g. semiconductor wafer manufacturing, biopharmaceutical WFI systems).

4. Physical properties

BA grade retains some mechanical strength and is suitable for piping systems that require some toughness6.

EP grade may slightly reduce the material thickness due to the polishing process, and is suitable for applications where very low fluid resistance is required.

To summarise

The division between BA and EP grades is based on different surface treatment processes and application requirements. BA grades are suitable for general high-purity environments, while EP grades are suitable for ultra-high-purity and highly corrosive media transport, such as semiconductors, biopharmaceuticals and other industries.

Post time: Apr-22-2025