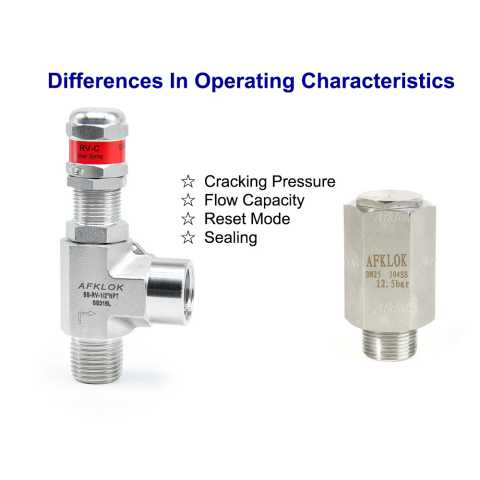

Safety valves and pressure relief valves are both devices used for pressure system protection, but they differ in their operating principles, application scenarios and functions. Correctly differentiating and selecting the right pressure setting is critical to system safety.

Difference between safety valve and pressure relief valve

1. Function and Principle of Operation

| Characteristics | Safety Valve | Relief Valve |

| Primary Purpose | Preventing explosion or equipment damage due to overpressure (safety protection) | Maintaining stable system pressure (process control) |

| Principle of operation | Full-opening type: Instantaneous full opening when pressure reaches the set value. | Rapid pressure relief Gradual: gradually open the valve with the rise of pressure, and gradually close it after the pressure is lowered. |

| Pressure relief method | One-time large amount of relief medium (such as steam, gas) | Small flow continuous or intermittent relief (such as liquids, compressible fluids) |

| Reset mode | Manual reset | Automatic reset |

- Applicable Scenarios

- Safety valves: used in high-pressure, high-risk situations (such as boilers, pressure vessels, chemical pipelines), to cope with sudden overpressure.

- Pressure relief valves: used in systems that require precise pressure control (such as hydraulic systems, water supply networks), regulating pressure fluctuations.

- Standards and certification

Safety valves are normally subject to stringent standards (e.g. ASME, API, GB/T 12241).

Pressure relief valves may comply with general pressure control standards (e.g. ISO 4126).

How to choose the right pressure setting

1. Determine the key parameters

- Set pressure (Set Pressure): the pressure at which the valve starts to operate.

- Safety valve: ≤ system design maximum pressure (usually 1.1 ~ 1.2 times the working pressure).

- Pressure Relief Valve: Slightly higher than the normal working pressure (e.g. 1.05~1.1 times the working pressure).

- Reseat Pressure: the pressure when the valve is closed (the safety valve needs to be checked to see if it meets the system recovery requirements).

- Overpressure allowable value: generally not more than 10% of the system design pressure.

2. Selection Steps

Evaluate the system requirements:

- Is it for sudden overpressure (select safety valve) or continuous regulation (select pressure relief valve)?

- Media type (gas/liquid/steam) and flow requirements.

Refer to regulatory standards:

For example, boiler safety valves need to comply with ASME Section I or GB/T 12243.

Calculate the pressure threshold:

- Safety valve set pressure ≤ vessel maximum allowable working pressure (MAWP).

- Relief Valve Set Pressure = Normal Working Pressure + Safety Margin (5~10%).

Verify relief capacity:

Ensure that the valve relief ≥ the maximum possible overpressure flow rate of the system (e.g., flow rate in case of pump/compressor failure).

3. Other considerations

- Media characteristics: corrosive media need to use special materials (such as stainless steel, Hastelloy).

- Environmental requirements: explosion-proof, low or high temperature environment requires special design.

- Testing and maintenance: safety valves need regular mandatory calibration (such as once a year), pressure relief valves can be online debugging.

Post time: Apr-07-2025