Routine maintenance intervals for special gas cabinets can be categorized as follows:

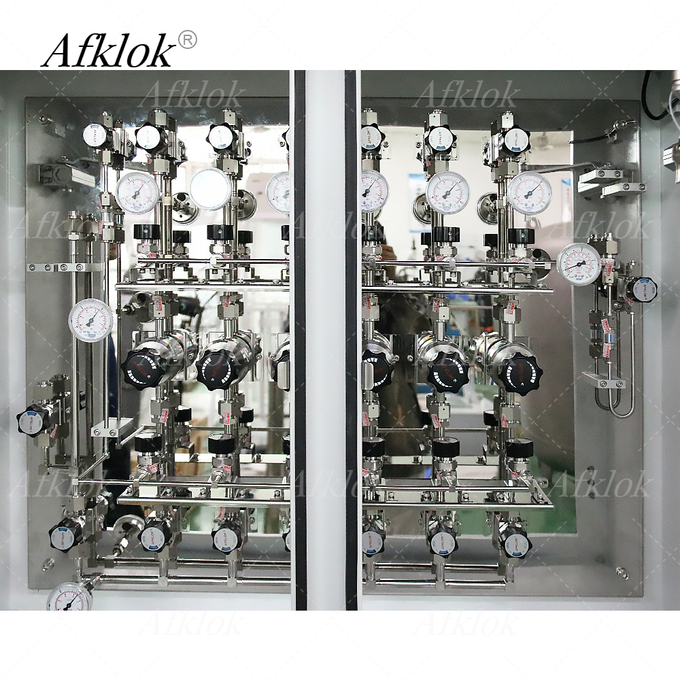

1. Daily maintenance: It is recommended that this be carried out twice a day. It mainly includes visual observation for damage, leakage and faulty parts; checking the process and purge gas pressure and comparing it with the standard and historical records; observing the inside of the gas cabinet for any signs of corrosion or gas leakage; and checking whether the display of the pressure gauge and pressure sensor is normal.

2. Regular focused maintenance:

For corrosive gas related valves and pressure reducing valves, do external leakage test every 3 months and replace if necessary;

For toxic or flammable gas related valves and pressure reducing valves, do external leakage test and inspection and maintenance every 6 months;

For inert gas related valves and pressure reducing valves, external leakage test and inspection and maintenance once a year.

3. Comprehensive Inspection: At least once a year, a comprehensive inspection should be carried out to inspect and evaluate in detail the overall operating condition of the special gas cabinet, the performance of each component, the sealing condition, the safety devices, and so on.

However, the above maintenance intervals are only general recommendations, the actual maintenance intervals may also vary depending on the frequency of use of the special gas cabinet, the use of the environment, the characteristics of the gas and the quality of the equipment and other factors. If the special gas cabinet is used frequently or in a more severe environment, it may be necessary to shorten the maintenance cycle and increase the frequency of maintenance.

Post time: Oct-08-2024