In industrial, medical and laboratory gas systems, CGA (Compressed Gas Association) series cylinder couplings are a key component to ensure the safe delivery of gases. However, with so many models and sizes available, many users are faced with the challenge of selecting the correct type. This article provides a comprehensive guide to the CGA range of cylinder couplings, helping you to select the most suitable product with ease.

I. Introduction of CGA Series Cylinder Connector

The CGA series of cylinder couplings is a standardised system of couplings developed by the Compressed Gas Association of the United States and is widely used for the connection of gas cylinders. Each CGA model corresponds to a specific gas type and application scenario, ensuring safety, compatibility and efficiency.

II.Key Factors in Selecting CGA Series Cylinder Connectors

1. Types of gases

- Inert gases: such as argon (Ar), nitrogen (N₂), helium (He), etc., commonly used CGA580, CGA320 and other models.

- Flammable gases: such as hydrogen (H₂), acetylene (C₂H₂), etc., commonly used CGA350, CGA510 and other models.

- Corrosive gases: such as chlorine (Cl₂), ammonia (NH₃), etc., need to choose corrosion-resistant materials (such as stainless steel) connectors.

- Medical gases: such as oxygen (O₂), laughing gas (N₂O), etc., commonly used CGA540, CGA870 and other models.

2. Application Scenario

- Industrial gases: choose high-pressure resistant and durable connectors, such as CGA580, CGA660.

- Medical gases: choose the connectors that meet the medical standard, such as CGA540, CGA870.

- Laboratory gases: choose high-purity, corrosion-resistant fittings, such as CGA320, CGA590.

3. Material selection

- Brass: suitable for most non-corrosive gases, lower cost.

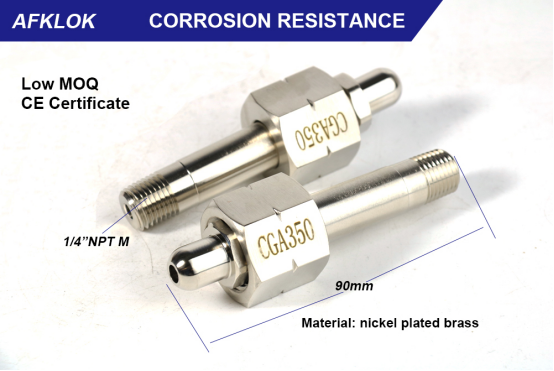

- Nickel-plated brass: improve corrosion resistance and wear resistance, suitable for moderately corrosive environments.

- Stainless steel: suitable for strong corrosive gases and high purity gases, with higher strength and durability.

4. Working pressure

Select the appropriate fitting according to the working pressure of the gas system. For example, high pressure gas system (such as hydrogen) need to choose high pressure resistant design fittings.

5. Seal type

Flat seal: Suitable for most gases, sealing is achieved by gaskets or O-rings.

Conical seal: Suitable for high pressure gases, better sealing performance.

III. Common CGA models and their applicable gases

| CGA Models | Applicable Gases | Typical Application Scenarios |

| CGA320 | Argon, Nitrogen, Helium | Industrial gases, laboratory gases |

| CGA350 | Hydrogen | Industrial gases, energy sector |

| CGA540 | Oxygen | Medical gases |

| CGA580 | Oxygen, nitrogen, argon | Industrial gases, medical gases |

| CGA590 | Oxygen | Medical gases |

| CGA660 | Argon, Carbon Dioxide | Welding Gases |

| CGA870 | Laughing gas (N₂O) | Medical gases |

IV. Selection Precautions

- Compliance with standards: Make sure the selected connector meets CGA standards to ensure safety and compatibility.

- Customised requirements: If there are special requirements (e.g. non-standard rod length, special materials), you can communicate with the supplier for customisation.

- Testing and certification: Choose products that have undergone rigorous testing and certification to ensure reliable performance.

- Supplier support: Choose suppliers with technical support and after-sales service in order to solve problems in use.

V. Successful Case Sharing

A laboratory needed to select CGA fittings for a high-purity hydrogen system, and finally chose CGA350 stainless steel fittings with a 9cm rod length. The coupling not only meets the requirements of high purity gas, but also passes the strict leakage test and pressure test to ensure the safety and reliability of the system.

VI. Conclusion

Correct selection of CGA series cylinder couplings is the key to ensure the safe and efficient operation of gas systems. By understanding factors such as gas type, application scenario, material selection and working pressure, you can easily select the most suitable connector. For further technical support or customised service, please contact us for further assistance.

About Us

As a professional supplier of CGA series cylinder couplings, we offer a wide range of models and customised services to meet the needs of different customers. Our products comply with CGA standards and undergo rigorous testing to ensure safety and reliability. Welcome to contact us for more product information and technical support!

Contact Information

Tel:0755 0927 0234 43

Email: info@szwofly.com

Official website: https://www.woflyvalve.com

Post time: Mar-15-2025