Lab Industrial Gas Manual Gas Panel for Both Cylinders

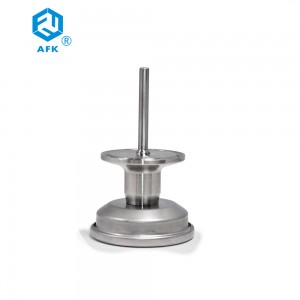

WL200 Double Gas Supply High Pressure Regulator Device

Characteristics of pressure reducer

The following factors need to be paid attention to when selecting the pressure reducer. Follow up the requirements of your specific use, and use this catalog to select the pressure reducer consistent with your parameters. Our standard is just the beginning of our service. We can modify or design control equipment to solve any problems in application.

Features of WL 200 High Pressure Regulator Device

| 1 | Pressure Regulator for special gas |

| 2 | Equipped relief pressure valve |

| 3 | Pressure regulator and pipe through the pressure test and leakage tes |

| 4 | 2 stainless steel gauges,reading clearly |

| 5 | The knob of diaphragm valves “on/off” logo |

Specification of Double Gas Supply High Pressure Regulator Device

| 1 | Body | SS316L, brass, nickel plated brass ( Weigh :0.9kg) |

| 2 | Cover | SS316L, brass, nickel plated brass |

| 3 | Diaphragm | SS316L |

| 4 | Stainer | SS316L(10um) |

| 5 | Valve Seat | PCTFE,PTFE,Vespel |

| 6 | Spring | SS316L |

| 7 | Plunger Valve Core | SS316L |

Specfications of High Pressure Regulator Device

| 1 | Maximun Input Pressure | 3000,2200 psig |

| 2 | Outlet pressure range | 0~25, 0~50, 0~100, 0~250, 0~500 psig |

| 3 | Working Temperature | -40°F~ +165°F (-40°C~ +74°C ) |

| 4 | Leakage Rate | 2×10-8 atm cc/sec He |

| 5 | Flow Rate | See Flow Curve Chart |

| 6 | CV Value | 0.14 |

|

WL2

|

1

|

1

|

1

|

S

|

H

|

1

|

1

|

-N2

|

|

Series

|

Function Options

|

Outlet Connection

|

Inlet Connection

|

Body Material

|

Input

Pressure

|

Outlet

Pressure

|

Gauge

|

Gas Option

|

|

WL200 Double Gas Supply High Pressure Regulator Device

|

1.With emptying, purging distribution function

|

1:1/4”NPT(F)

|

1:1/4″Weldmg

|

S:stainless

|

H:3000psi

|

1:25psi

|

1:MPa

|

Blank: None

|

|

|

2.Wrthout Emptying, purging distribution function

|

2:1/4”Tube fitting

|

2:1/4”NPT(M)

|

steel

|

M:2200psi

|

2:50psi

|

2:Bar/psi

|

N2:nitrogen

|

|

|

3.Emptying. purging distnbuUon+pressure sensor

|

3:3/8”NPT(F)

|

3:3/8”Melding

|

C:nickel plated

|

L:1000psi

|

3:100psi

|

3:psi/KPa

|

O2:oxygen

|

|

|

4.With pressure sensor

|

4:3/8”Tube fitting

|

4:3/8”NPT(M)

|

brass

|

O: Other

|

4:150psi

|

4:Other

|

H2:hydrogen

|

|

|

5:Other

|

5:1/2”NPT(F)

|

5:1/2”Melding

|

|

|

5:250psi

|

|

C2H2:acetylene

|

|

|

|

6:1/2”Tube fitting

|

6:1/2”NPT(M)

|

|

|

6:Other

|

|

CH4:methane

|

|

|

|

7:Other

|

7:1/4”Tube fitting

|

|

|

|

|

Ar:argon

|

|

|

|

|

8:3/8″Tube fitting

|

|

|

|

|

He:helium

|

|

|

|

|

9:1/2″Tube fitting

|

|

|

|

|

Air:air

|

|

|

|

|

10:Other

|

|

|

|

|

|

In short, the latest concept of PCR laboratory is to treat the whole laboratory as a fume extraction cabinet. How to effectively control the various intake and exhaust air to achieve safe and economic results is crucial. the main fume hoods used in PCR laboratories are: fume cabinets, atomic absorption cabinets, universal exhaust cabinets, ceiling exhaust cabinets, bench top exhaust cabinets, etc., of which fume hoods are the most common.