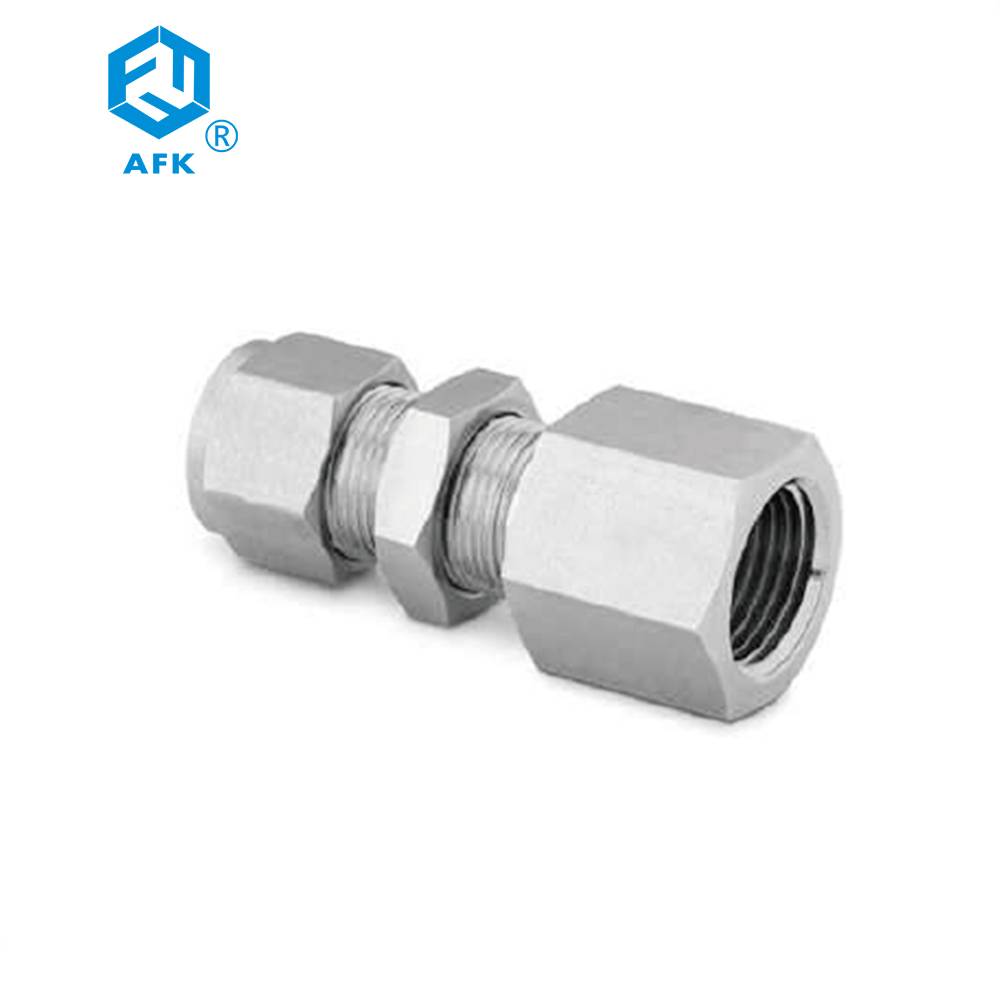

China Wholesale High Pressure Cylinder Argon Factories - 1/4OD SS316 Double Ferrule Ccompression Tube Fitting – Wofly

China Wholesale High Pressure Cylinder Argon Factories - 1/4OD SS316 Double Ferrule Ccompression Tube Fitting – Wofly Detail:

Connects Fractional(inch) Tube

|

Part No. |

TubeOD T |

Dimensions (mm) |

||||||||

|

E Min. |

h |

H |

F |

I |

L |

|||||

|

Inch |

mm |

inch |

mm |

Inch |

mm |

|||||

|

U-01 |

1/16 |

1.58 |

1.3 |

5/16 |

7.93 |

5/16 |

7.93 |

8.6 |

17.5 |

25.1 |

|

U-02 |

1/8 |

3.17 |

2.3 |

7/16 |

11.11 |

7/16 |

11.11 |

12.7 |

22.4 |

35.6 |

|

U-03 |

3/16 |

4.76 |

3.0 |

7/16 |

11.11 |

1/2 |

12.70 |

12.7 |

24.1 |

37.3 |

|

U-04 |

1/4 |

6.35 |

4.8 |

1/2 |

12.70 |

9/16 |

14.28 |

15.2 |

26.2 |

40.9 |

|

U-05 |

5/16 |

7.93 |

6.4 |

9/16 |

14.28 |

5/8 |

16.87 |

16.3 |

28.2 |

42.9 |

|

U-06 |

3/8 |

9.52 |

7.1 |

5/8 |

15.87 |

11/16 |

17.46 |

16.8 |

30.2 |

45.0 |

|

U-08 |

1/2 |

12.70 |

10.4 |

13/16 |

20.63 |

7/8 |

22.22 |

22.9 |

31.0 |

51.3 |

|

U-10 |

5/8 |

15.87 |

12.7 |

15/16 |

23.81 |

1 |

25.40 |

24.4 |

31.8 |

52.1 |

|

U-12 |

3/4 |

19.05 |

15.7 |

1-1/16 |

26.98 |

1-1/8 |

28.57 |

24.4 |

33,3 |

53.6 |

|

U-14 |

7/8 |

22.22 |

18.3 |

1-3/16 |

30.16 |

1-1/4 |

31.75 |

25.9 |

35.1 |

55.4 |

|

U-16 |

1 |

25.40 |

22.4 |

1-3/8 |

34.92 |

1-1/2 |

38.10 |

31.2 |

40.4 |

64.8 |

|

U-20 |

1-1/4 |

31.75 |

27.7 |

1-3/4 |

44.45 |

1-7/8 |

47.63 |

41.1 |

48.0 |

92.2 |

|

U-24 |

1-1/2 |

38.10 |

34.0 |

2-1/8 |

53.97 |

2-1/4 |

57.15 |

50.0 |

53.6 |

108.0 |

|

U-32 |

2 |

50.80 |

46.0 |

234 |

69.85 |

3 |

76.20 |

67.6 |

74.7 |

149.4 |

Connects Metric Tube

|

Part No. |

Tube OD T |

Dimensions (mm) |

|||||

|

E Min. |

h |

H |

F |

I |

L |

||

|

mm |

inch |

mm |

|||||

|

U-M02 |

2 |

1.7 |

11.11 |

11.11 |

12.9 |

22.4 |

35£ |

|

U-M03 |

3 |

2.4 |

11.11 |

11.11 |

12.9 |

22.1 |

35.3 |

|

U-M04 |

4 |

2.4 |

11.11 |

1270 |

13.7 |

24.1 |

37.3 |

|

U-M06 |

6 |

4.8 |

12.70 |

14.28 |

15.3 |

26.2 |

41.0 |

|

U-M08 |

8 |

6.4 |

14.28 |

15.87 |

162 |

282 |

43.2 |

|

U-M10 |

10 |

7.9 |

17.46 |

19.05 |

172 |

31.0 |

46.2 |

|

U-M12 |

12 |

9.5 |

20.63 |

22.22 |

22.8 |

31.0 |

51.2 |

|

U-M14 |

14 |

11.1 |

23.81 |

26.40 |

24.4 |

31.8 |

52.0 |

|

U-M15 |

15 |

11.9 |

23.81 |

25.40 |

24.4 |

31.8 |

52.0 |

|

U-M16 |

16 |

12.7 |

23.81 |

25.40 |

24.4 |

31.8 |

52.0 |

|

U-M18 |

18 |

15.1 |

26.98 |

30.16 |

24.4 |

33.3 |

53.5 |

|

UW22 |

22 |

18.3 |

30.16 |

31.75 |

26.0 |

34.8 |

55.0 |

|

U-M25 |

25 |

21.8 |

34.92 |

38.10 |

31.3 |

40.4 |

65.0 |

|

U-M28 |

28 |

21.8 |

44«45 |

47.63 |

36£ |

43.4 |

85.0 |

|

U-M30 |

30 |

26.2 |

44/15 |

50.80 |

39.6 |

49.5 |

92.7 |

|

U-M32 |

32 |

28.6 |

4445 |

50.80 |

42.0 |

51.3 |

97.3 |

|

U-M38 |

38 |

33.7 |

55.56 |

57.15 |

49.4 |

58.4 |

114.0 |

This size is for reference only, subject to possible changes in the actual product (without notice).

E refers to the smallest opening. F and L are the standard hand-tightened dimensions.

Tube Fitting

–Available in tube sizes from 1/16 in. to 2 in. & 2mm to 50 mm.

–Easy to disconnect and retighten.

–Wide variety of materials and configurations.

Introduction

Afklok Engineers are designed as leak free connection for process, power & Instrumentations applications. These two ferrule fttings are manufactured to the high test quality standards & available in a large of sizes, materials and configurations.

Features

Afklok Tube Fittings has been designed for use in instrumentations, process & control systanalyses and environment employed in chemical, petroleum, power generating, pulp & paper plants. Afklok tube ftting has also found special application in other fields where high pressure tube ftting has also found special application in other fields where high pressure tube fttings are required.

If more specific information, including heat code traceability. Afklok tube fttings work reliably on both seamless & welded – redrawn fully, annealed type 304, 306 & 316L tubing.

Materials

Afklok Tube Fittings are available as standard in Heat Code Traceable, SS316, SS316L, SS304. Straight fttings are machined from cold finished bar stock& shaped bodies are machined from high quality forging. The Raw materials used fully conforming to chemical requirements as per respective material specifications.

Two ferrule compact design

Tube ftting have been designed and manufactured with great care to meet the specifications required for wide range of applications in chemical, petro chemical, oil refinery, power generation, shipbuilding, pulp & paper, micro electronics, etc. The double ferrule ftting consists of four parts body, front ferrule, back ferrule & nut. This two ferrule design consists of front & back compensates for any tolerances in tube OD,wall thickness, material hardness & always secure Heak proof joints capable of high pressure, vacuum & vibration applications. Allows the front ferrule to seal while the back ferrule grips. Uses consistent geometry (instead of torque for gauge able make-up. Overcomes variations in tube materials, wall thickness & hardness. Provides excellent vibration resistance. Allows reliable remake connections.

Product detail pictures:

Related Product Guide:

It is a great way to further improve our products and repair. Our mission is always to create innovative products to prospects with a superior expertise for China Wholesale High Pressure Cylinder Argon Factories - 1/4OD SS316 Double Ferrule Ccompression Tube Fitting – Wofly , The product will supply to all over the world, such as: Chicago, Jordan, Czech Republic, If any product meed your demand, please feel free to contact us. We're sure your any inquiry or requirement will get prompt attention, high-quality products, preferential prices and cheap freight. Sincerely welcome friends all over the world to call or come to visit, to discuss cooperation for a better future!

Good quality, reasonable prices, rich variety and perfect after-sales service, it's nice!