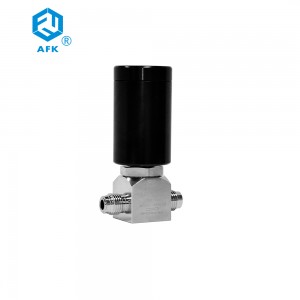

1/4in 150psi High Quality High Purity Gas Nitrogen Oxygen Helium Low Pressure Manual Stainless Steel Diaphragm Valve OEM

Product Description of Low Pressure Manual Diaphragm Valve

Features

1. Metal-to-metal seal for leak-free service in the vacuum to high pressure range

2. Small internal volume for complete purging of the flow path

3. Fully encapsulated valve seat design for greater durability and corrosion resistance

4. Nickel-cobalt alloy diaphragm for greater durability and corrosion resistance

5. Standard roughness of Ra0.25μm (BA grade) or electrolytic polished Ra0.13μm (EP grade) available

6. Leakage rate <1 x 10-9 std cm3/s in helium test

7. Pneumatic actuators available

8. Pneumatic valve life up to 3 million cycles

Specification of Low Pressure Manual Diaphragm Valve

| Technical data | |

| Port size | 1/4″, 3/8″ |

| Flow coefficient (Cv) | 0.27 |

| Inner diameter | 0.16 in. (4.1 mm) |

| Maximum working pressure | 10 bar (150 psig) |

| Pneumatic actuator working pressure | 4.2~6.2 bar (60~90 psig) |

| Operating temperature | PCTFE:-23~65℃(-10~150℉)PFA:-23~150℃(-10~302℉) |

| Leakage rate (helium) | ≤1×10 mbar l/s |

| ≤1×10 mbar l/s | |

| Flow data | ||

| Air @ 21°C (70°F) 10.2Water @ 16°C (60°F) | ||

| Pressure drop to atmospheric pressure bar (psig ) | Air (l/min) | Water (l/min) |

| 0.68 (10) | 86 | 3.2 |

| 3.4 (50) | 230 | 7.2 |

| 6.8 (100) | 410 | 10.2 |

Cleaning process

Standard (WK-BA)

Welded joints are cleaned according to our standard cleaning and packaging specifications, to be ordered without the addition of a suffix

Cleaning for oxygen (WK – O2)

Product cleaning and packaging specifications for use in oxygen environments are available, and this meets ASTM G93 Class C cleanliness requirements; to order, add -O2 to the ordering number

Ultra High Purity (WK-EP)

Available in controlled surface finish, electrolytically polished Ra 0.13μm, ultrasonically cleaned in deionised water. To order, add – EP to the order number

|

Basic Order Number |

Port types and sizes |

Dimensions in.(mm) |

|||

|

A |

B |

C |

L |

||

| WV4-6L-TW4- | 1/4″ Tube butt weld fittings |

0.44 (11.2) |

0.30 (7.6) |

1.06 (26.9) |

1.74 (44.2) |

| WV4-6L-TW6- | 3/8″ Tube butt weld fittings |

0.44 (11.2) |

0.26 (6.6) |

1.06 (26.9) |

1.74 (44.2) |

| WV4-6L-FR4- | 1/4″ female thread MCR fitting | 0.44 (11.2) | 0.86 (21.8) | 1.06 (26.9) | 2.78 (70.6) |

| WV4-6L-MR4- | 1/4″ integral male MCR fitting | 0.44 (11.2) | 0.62 (15.7) | 1.06 (26.9) | 2.24 (57.0) |

1. who are we?

We are based in Guangdong, China, start from 2011,sell to Southeast Asia(20.00%),Africa(20.00%),Eastern Asia(10.00%),Mid East(10.00%),Domestic Market(5.00%),South Asia(5.00%),Northern Europe(5.00%),Central America(5.00%),Western Europe(5.00%),South America(5.00%),Eastern Europe(5.00%),North America(5.00%). There are total about 51-100 people in our office.

2.How do I order?

You can order it from Alibaba directly or send us a inquiry. We will reply you within 24 hours

3.Do you have any certificates?

We have CE certificate.

4. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

5.what can you buy from us?

pressure regulator,Tube fittings,solenoid valve,Needle valve,check valve

6. why should you buy from us not from other suppliers?

We have a couple of years with professional engineers and dedicated technicians.can provide security products for you

7. what services can we provide?

Accepted Delivery Terms: FOB,CIF,EXW;

Accepted Payment Currency:USD,CNY;

Accepted Payment Type: T/T,L/C,Western Union;

Language Spoken:English,Chinese